Ultrasonic Flow Meter Working Principle Ppt

In my previous video https youtu be 8llrbvlydbo i told the working principle of variable area flow meter and in todays video i want to tell about the meas.

Ultrasonic flow meter working principle ppt. The ultrasonic signals are generated by piezo electric crystals applying a voltage. This time difference is a measure for the average velocity of the fluid along the path of the ultrasonic beam. The canoe moving with the flow needs much less time to reach the opposite bank. The ultrasonic waves strike particles moving through the sound field at velocity vp.

Ultrasonic flow meters operate using the transit time differential method. The working principle of ultrasonic flow meter is it uses sound waves to resolve the velocity of a liquid within a pipe. Imagine two canoes crossing a river on the same diagonal line one with the flow and the other against the flow. It is also a common practice to use a clamp on ultrasonic flow meter to verify other flow meters or for temporary measurement.

Some ultrasonic flowmeters use clamp on transducers that can be mounted external to the pipe and do not have any wetted parts. Ultrasonic flow meters working principle s bharadwaj reddy july 29 2016 july 21 2019 ultrasonic flow meters operate using the transit time differential method. Conversely the piezo electric crystal creates a. 1 5 mhz at angle a into the flowing product.

The transit time differential measurement is based on a simple physical fact. Temporary flow measurements can be made using portable ultrasonic flowmeters with clamp on transducers. Simultaneously the transit time of these signals are measured. In the first condition the frequencies of ultrasonic waves are transmitted into a pipe its indications from the fluid are similar.

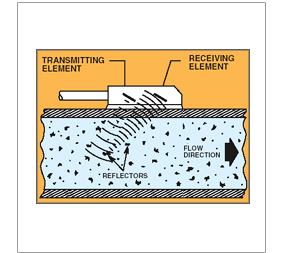

Ultrasonic flow meters have many applications from process flow to custody flow. Principle doppler flow meters operate similarly to the radar speed traps used on the road. The article explains what you need to know about the basics of ultrasonic flow measurement and its applications. Each sensor alternately can transmit and receive ultrasonic signals.

An emitter sends ultrasonic waves at frequency f1 approx. There are two conditions in the pipe like no flow and flowing.